The center has available a wide spectrum of thin film deposition tools, spanning various forms of sputter deposition and molecular beam epitaxy.

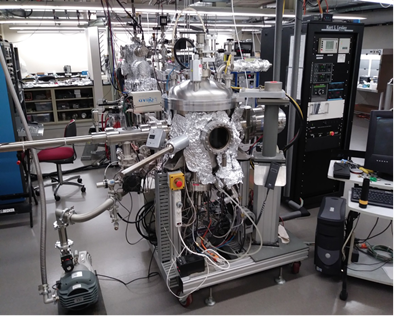

High-pressure-oxygen sputter deposition system

This unique system is dedicated to the growth of epitaxial thin films and heterostructures of complex oxides. It enables growth at up to 1000 °C in several-Torr pressures of pure O2, for epitaxy of even difficult to oxidize materials. The system is used heavily for CQM research on perovskite oxides.

General-purpose UHV sputter deposition system

This modified Kurt J. Lesker CMS-18 tool enables deposition from up to six sources, spanning metals, insulators, oxides, nitrides, etc. This load-locked system is ultra high vacuum (UHV), offers substrate temperatures up to 850 °C, and can be used for reactive deposition with O2 and N2.

Sulfide sputter deposition system

This unique home-built system allows for reactive high-temperature deposition of metal sulfides from three targets in a H2S/Ar mix. It is used solely for deposition of sulfide films, such as FeS2, NiS2, and so on.

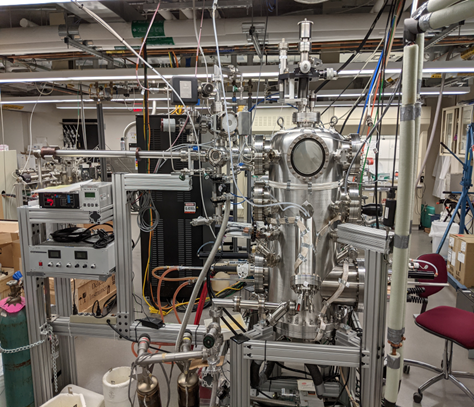

Metal MBE system

This true-UHV molecular beam epitaxy (MBE) system offers 1000 °C deposition temperatures, eight electron-beam sources, three thermal cells, in situ Ar ion milling, load-lock oxidation, and reflection high-energy electron diffraction. The system is used primarily for metal layer and heterostructure deposition.

Funded by the Department of Energy under DE-SC0016371