Optical floating-zone furnaces

Three optical floating-zone furnaces allow for crucible-free growth of large, high-quality crystals. These furnaces use focused light to melt a precursor feed rod and grow a crystal from a seed crystal. The furnaces are capable of temperatures exceeding 2000 °C under a variety of controlled atmospheres.

Box furnaces

Standard box furnaces are used for the bulk fabrication, including the growth of the Hg-based cuprates using the encapsulated self-flux growth method. The Center has 12 standard box furnaces with maximum temperatures of 1100 - 1200 °C, and a high-temperature muffle furnace capable of up to 1600 °C. Many of the furnaces can run a customized temperature vs time program. Sealing the growth materials in a welded quartz tube allows for high vapor pressures during crystal growth.

Tube furnaces

Tube furnaces are used for crystal growth by chemical vapor deposition, post-growth annealing, and heat treatment. These include eight one-zone furnaces capable of up to 1100 °C, and two three-zone furnaces with maximum temperatures of 1200 °C and 1350 °C. Most of these furnaces are equipped with manifolds for gas flow and/or high-vacuum pumping.

Chemical vapor transport furnaces

The Leighton Lab houses two vapor-transport setups based on three-zone furnaces with high capacity. Each system is set up to enable six parallel growths in quartz tubes, greatly increasing sample throughput. These systems are used for growth of doped pyrite NiS2, and delafossite PdCoO2 and PdCrO2, for example.

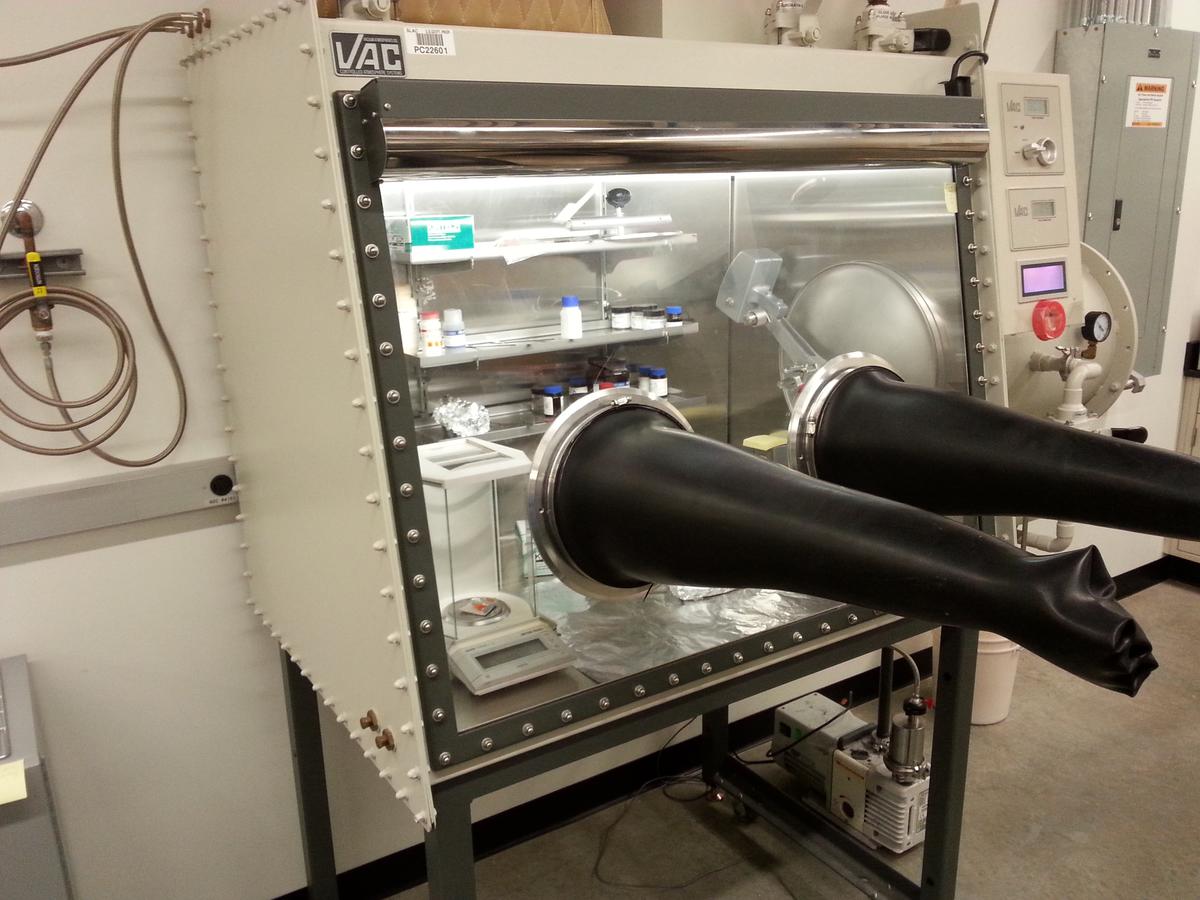

Material handling equipment

The Center has three glove boxes and numerous fume hoods for safely handling hazardous materials and maintaining the purity of chemicals and samples during crystal growth preparation and sample preparation.

Funded by the Department of Energy under DE-SC0016371